Having passed the total Cyrel Fast installations of 1,500 in 2019, DuPont celebrates the 150th site for the latest generation Cyrel Fast 2000 TD. The landmark plate machine went into flexo print house Marpol Sp. In Northern Poland.

Based on its positive experience with DuPont Cyrel Fast thermal technology prior generation in 2008, Marpol decided to invest into the latest generation and installed a Cyrel Fast 2000 TD thermal processor, marking the 150th global installation of this latest series.

Robert Arwuk, Marpol’s Director of Production, says: “The new DuPont thermal processor meets all our expectations. Maintaining colour consistency, especially on reprints or series of projects, is just as important as being able to, almost instantaneously, produce a photopolymer plate. In case of a design change or correction by the customer, a new plate is required in the shortest time and, with Cyrel Fast technology, Marpol is able to have a new plate ready in less than an hour.”

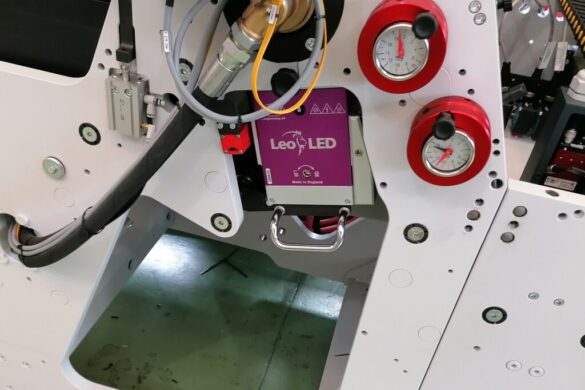

Arwuk adds: “Remote diagnostics allows for real-time monitoring of the machine parameters and speeds up the reaction time in case of breakdowns.”

Pioneering plate technology

DuPont pioneered the Fast thermal flexographic platemaking technology around 20 years ago and is a leading supplier in thermal technology, having installed over 1,500 units of all generations.

Marpol is a leading manufacturer of flexible packaging foils in the Polish market. The company started operation in 1994, producing LDPE foils on its own extruders. In 1998, the first flexo press was installed, along with a prepress studio. Today, two plants operate, one in Poland’s North and one in the South, and combined, operate with four extrusion lines, seven flexo machines as well as six laminators and nine cutters, plus two lines for the production of flat bags and doypacks (stand-up pouches). Marpol employs over 300 people.

“We process several thousand square metres of photopolymer a year and, thanks to the greater production capacity of the Cyrel Fast 2000 TD, we will also be able to produce plates for our southern plant, which doesn’t have its own prepress studio,” says Arwuk.

A sustainable solution

Sustainability is a very important element of Marpol’s company policy. Apart from overall environmental packaging trends, the company also focuses on eco-friendly technologies for production. The latest generation of Cyrel Fast platemaking system fits perfectly into this model. It emits virtually only warm air, practically eliminating volatile organic compound (VOC) emissions — a 99 percent reduction compared to solvent technology.

Tomasz Nojszewski, sales manager at DuPont Image Solutions, Poland says: “The first generation of Cyrel Fast was a revolution — the latest generation is an evolution. Compared to the first generation of Cyrel Fast, we’ve re-designed virtually everything, from the way the plate is pinned (no more rotating drum with compressible surface and special adhesive surface), to a much more precise system for removing monomer from non-printing components and improved environmental performance.”

He adds: “Compared to the previous generation, the Cyrel Fast 2000 TD has 76 percent lower VOC emissions, which is ahead of the current norm and, compared to solvent technology, it consumes 63 percent less non-renewable energy.”

All Cyrel products are available through DuPont Australia and authorised dealers.

www.cyrel.com