Label Power has been appointed as the Australian distributor for Eclipse high-speed narrow web label finishing machines. Manufactured in the United Kingdom, Eclipse has created a whole new sector for the label industry – compact footprint machines that digitally cut, laminate, strip, slit and rewind preprinted label stocks.

Designed for flexibility of label production – from bespoke luxury brands, presented in low volumes right through to larger-sized label designs produced in industrial quantities – the Eclipse has an impressive optimal production cutting speed of 4.6 metres per minute. It can run on various substrates including papers of all types – coated and non-coated, BOPP, polyester, vinyl to name a few. Customers no longer need to keep an expensive range of pre-cut stocks on hand, reducing their financial costs instantly.

James Malone, Owner of Label Power, says: “Eclipse label finishing equipment is suitable for both small or large manufacturing and multi-production warehouse’s functions. It can be used to assist with keeping your label stock in check, only producing the right number of labels to coincide with your production runs. The larger 350mm wide machines are suitable for use with roll-to-roll UV inkjet presses, HP Indigo label presses or Konica Minolta roll-to-roll toner presses.

“Basically, Eclipse label finishing equipment is an unbeatable in-house response unit, saving you time and money and best of all, Eclipse label finishing equipment allows you to take back control of all your label stock, and save on your warehouse space.”

There are four machines in the range:

- The Eclipse Mini+ is the most popular label finisher that comes with all the specifications you would find in large-sized industrial label finishing equipment.

- The LF-220HS fast-track label cutting and finishing machine by Eclipse delivers high-speed labels up to 8.5 metres per minute. This economical space-saving model has a small footprint developed to sit neatly in the corner of the factory or workshop on a sturdy bench. It is designed to handle large bulk label orders and short runs, using digital drag knife technology developed using Summa technology. Cutting dies are not required.

- The LF-350S for webs up to 350 mm wide has been designed and developed specifically for end users wishing to produce medium to large bulk orders. It features dual cutting and barcode options, reading for different shape selections and label lengths up to 800 mm.

- The LF-350HS for webs up to 350 mm wide is the very latest fast-track label cutting and finishing machine by Eclipse, with a medium footprint. It delivers high-speed labels up to 10.5 metres per minute.

“The Eclipse Mini+ works well with the OKI PRO and Epson label printers that we sell,” observes Malone. “There is even an option to run the Eclipse Mini+ inline with the Epson C6510 inkjet printer to cut, strip and rewind or to laminate, cut strip and rewind.”

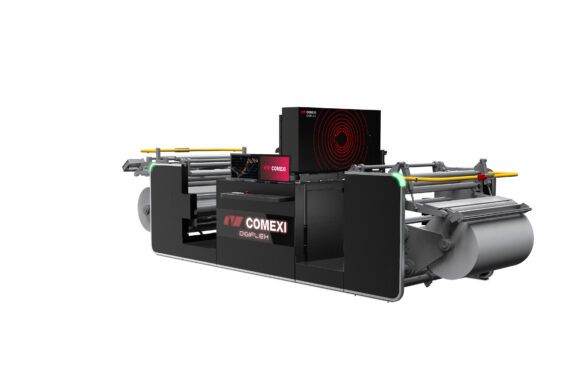

Caption:

The Eclipse Mini+ has all the specifications you would find in large-sized industrial label finishing equipment