When friends Marc de Amicis and Nigel Gainey slipped out for a quiet beer in Florence during a combined family holiday to Italy in 2012, little did they know that the label on a Peroni beer would lead, just 12 months later, to the duo establishing a world-first company – and leading Australia in digital label production.

Art director and prepress specialist Nigel recognised the novelty and potential of digital labels, while Marc, with business nous gained through years of sales and operational management, recognised the business opportunity inherent in taking the lead with new technology. The die, as they might say in an analogue world, was cast. Today, the pair can look back on a decade of partnership, as their business, New Digital Print, continues to grow from strength to strength.

“Launching the country’s first digital label business from scratch was probably a bit ambitious, but we’d seen the rise of local craft and farmers markets and noted the general trend towards short-run, customised labels, and felt the time was right,” Marc recalls, saying the proliferation of niche products like craft beers and gins from micro-distilleries since then has proven the theory correct.

From the start, the two have been ‘early adopters’, with both their initial digital toner press and an inkjet printer they added in 2017, the first of their kinds in the country. A small converter was purchased to support the initial presses, but the installation of the second machine together with business growth soon stretched resources.

“That second press pushed our converting to capacity almost immediately, sending us back out to market for a digital finishing and embellishment solution,” Marc explains, “and after talking to several suppliers, reviewing the latest options and visiting LabelExpo in Brussels in 2019, we settled on the new ABG DigiJet from Currie Group.”

Wayne Quayle, Business Development Manager Labels & Packaging at Currie Group, says the high-speed DigiJet provides the ultimate flexibility in cost-effective high-end finishing – in an easy-to-use machine that integrates seamlessly with most MIS / ERP environments.

“The DigiJet is available in single- or dual-bar configurations and can be used online or offline to apply multiple processes in a single pass using two inkjet heads with UV pinning and UV curing, automated cold-foil throw-off, a shuttle system for waste reduction and chill rollers for sensitive materials and a host of other features,” he says.

“The integrated JetFX digital embellishment module can accept any graphic file in grey scale to produce everything from cold foil, to spot varnish up to 225 microns in depth, soft-touch finishes, tactile screen effects and more; all with no tooling and virtually instant automatic job changeover, on the fly. You can even print solid varnishes and fine details on the same label, or customise product with variable data. It’s very impressive.”

Marc agrees, saying seeing the machine in action at LabelExpo ‘blew us away’. “The quality and range of options on coated, uncoated and synthetic stocks, with both toner and inkjet print, just ticked every box,” he says. “We could see it was the best on the market.”

This ‘Rolls Royce’ approach to investment is unusual for a start-up, and Marc admits it caused a couple of sleepless nights before their first job came through the door. But it’s proven a sound one, especially through the pandemic.

Quality speaks for itself

“Digital allows us to capitalise quickly on new opportunities, and quality speaks for itself,” he says. “We’ve had people so impressed with one of our labels that they’ve tracked us down to give us their work – and with the results we’re already achieving with the DigiJet, that’s only going to continue. Our designers are so excited about the possibilities, and we’re really enjoying showing our clients how we can enhance their labels.”

Clinching the deal was the knowledge that the DigiJet is backed by one of the industry’s longest-standing and most reliable suppliers, with Marc and Nigel agreeing that the service and support from factory-trained technicians at Currie Group give them ‘vital peace of mind’.

This obvious alignment of the pair’s vision and approach, together with their complementary skills makes this an ideal partnership, but Marc says their main strength is far more important: Friendship.

“From the start, we figured if we could still like each other after living with each other for six weeks on holiday, there was a good chance we’d survive working together,” he laughs. “Ten years on, our bond is even stronger, the business allows us to spend more time with our families – and technology like the ABG DigiJet means we’re still excited about the possibilities the future holds.”

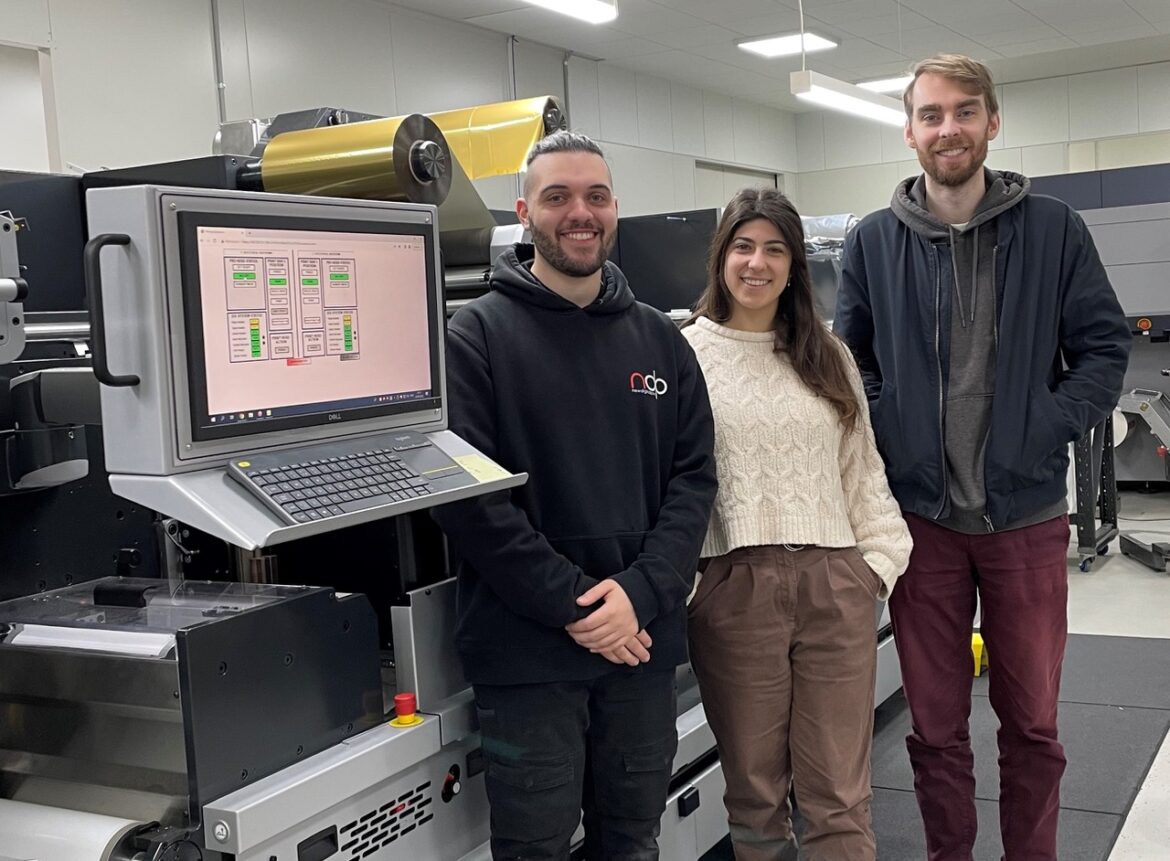

Caption:

Gianni De Amicis (2IC), Claudia Tigani (Pre Press Co-ordinator) and Harrison Bender (Pre Press)