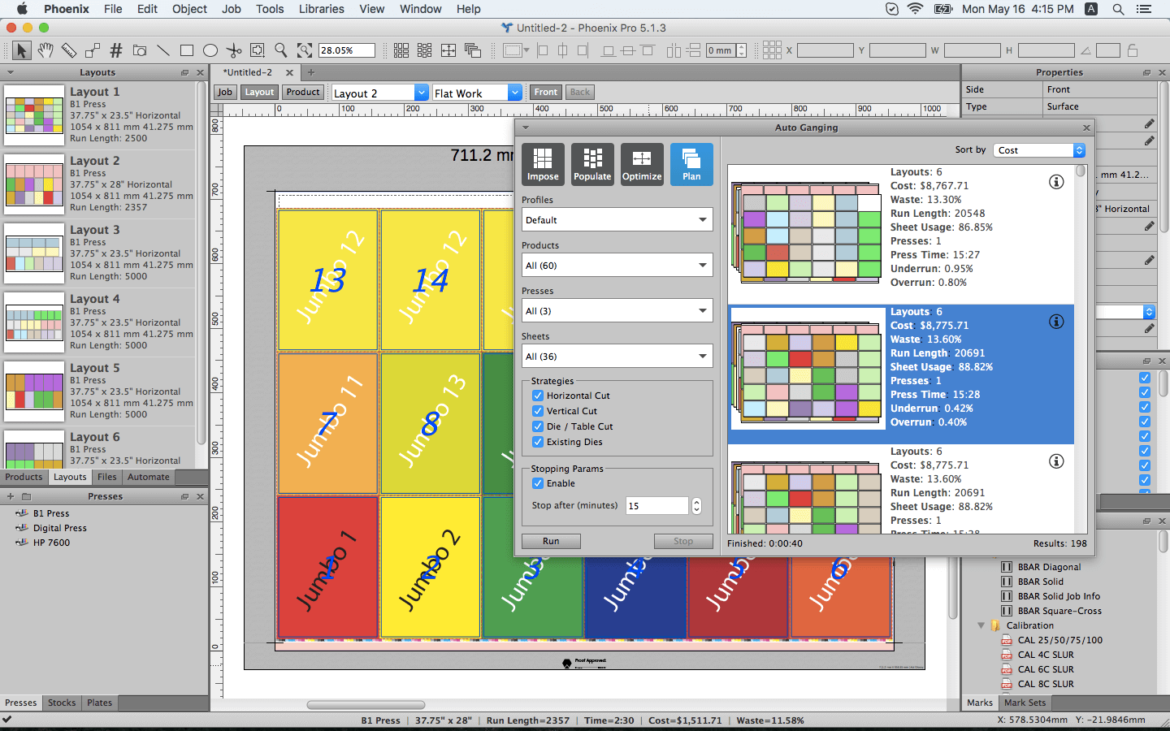

Tilia Phoenix is a highly powerful, AI-based impositioning tool that auto-populates die cavities based on ordered quantities. Thanks to Tilia Lab’s development of its CERM Connector, the CERM MIS – Phoenix integration is now a completely seamless and cross-platform layout optimiser tool for folding carton, packaging and sheetfed label production.

Integration with the layout optimiser is available in the CERM MIS during the estimation and job management processes. In both applications, the CERM MIS operator instantly gets different impositioning solutions, from which the operator can select a preference. Tilia Phoenix calculates the best layout solutions based on the operator’s strategy of choice: least possible waste, lowest production time, lowest production cost, or lowest number of sheets used.

Tyler Thompson, Solutions Director for Tilia Labs, says: “Our customers know that integrated software solutions deliver the biggest impact, especially when best-in-class companies work together. The integration with CERM and Tilia Labs enables estimators and planners to find the most cost-efficient production plans in seconds, with mission-critical data pushed back into CERM in real time.”

In estimation, multiple shapes are ganged and nested for one or multiple given paper sizes. In job management, products are ganged based on an existing die-cut tool layout, but the software also provides solutions for new nested impositions. The output of the calculation is stored in the CERM MIS.

For more information on Tilia Labs Phoenix visit https://tilialabs.com/products/phoenix/

Caption:

The CERM MIS – Phoenix integration is a completely seamless and cross-platform layout optimiser tool