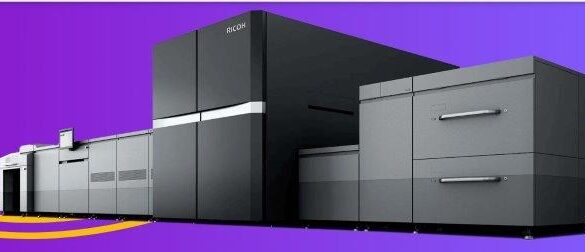

Xeikon introduced the Panther PX3300 UV inkjet label press to visitors at PacPrint in the first showing of the Xeikon Panther 2.0 technology in Australia. The high-end UV inkjet press was the focal point on Xeikon’s centrally-located stand at the MCEC.

Built for the production of highly durable labels with high scuff resistance and print quality that matches that of screen and flexo print, the flagship machine was first unveiled towards the end of last year, as the next evolution of Xeikon’s high-productivity inkjet portfolio.

It offers full rotary printing at variable repeat length with CMYK or CMYK plus white UV inks, which are sunlight, water, chemical, temperature and mechanical resistant, allowing printers to address the industrial, chemical and household markets, as well as the premium beer, spirits, beverages and luxury health and beauty sectors.

“We were excited to bring the Xeikon PX3300 to Australia to show customers what our Panther UV inkjet technology can deliver in terms of high quality, speed, durability and versatility. This press will enable printers to get into new markets where high durability is expected, and really change the game for them,” said Trevor Crowley, Sales General Manager at Xeikon. “We also offer full colour variable data capabilities with the Vari-One option, while the white UV ink can create embellishments and haptic effects inline for a luxury feel.

“After the extreme challenges of the Covid pandemic, we were delighted to be back at PacPrint to connect with our customers face-to-face. Our industry thrives on in-person networking and a hands-on approach. So as much as we can extol the virtues of Xeikon technology during online presentations and virtual events, you really need to get up close and personal with the machinery to truly understand their power and the opportunities they can bring to your business,” concluded Crowley.

Caption:

Trevor Crowley, Sales General Manager at Xeikon with the Panther PX3300 at PacPrint