Eclipse Label Finishing Equipment will launch not one but two new highly anticipated disruptive products: a laser label finisher with a difference and a full inline label finishing station compatible with many printers.

Thanks to its extensive market experience and its partners’ network globally, Eclipse stays very close to the market pulse and has identified the need of many label producers to combine printing and finishing, all in one process. This not only results in reduced labour interventions and better label production efficiencies but also improves reactivity while keeping costs down.

Eclipse products offer an all-in-one finishing solution to small and medium-sized businesses, from start-ups to established medium size industrial companies. Instead of having two processes – printing and finishing – Eclipse customers can now reap the benefits of what an inline system brings even if their label production volumes are modest.

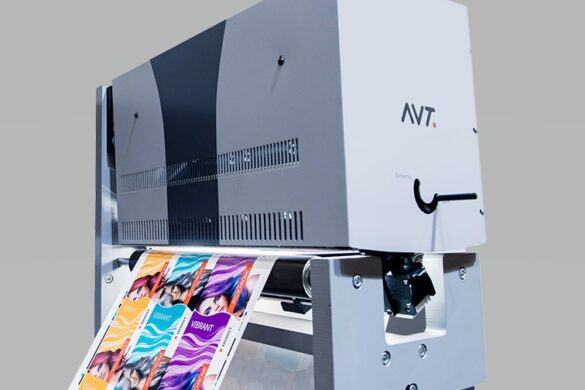

The LF220LAS takes label finishing to the next level

Targeted at medium to large industrial users, the LF220LAS is ideal for companies willing to finish their labels efficiently, whether the labels come from a roll or directly from a printer.

Built and designed entirely in the UK, the LF220LAS offers unprecedented label finishing possibilities by combining the finishing associated with lasers (speed, accuracy, extreme precision, non-contact) with the capability of being able to get labels from a pre-printed roll (up to 400 mm in diameter and 220 mm wide) or directly from a printer thanks to a system of integrated dancer bars that fully regulate and synchronise the supply of label into the finisher.

The innovative concept is set to appeal to demanding customers that want flexibility and label-producing performances.

Some key LF220LAS features and benefits:

- UK top build quality, floor mounted

- 120W laser (water cooled) ensuring extreme precision, non-contact cut, consistent label production (no wear and tear)

- Label shapes can be as complex as desired within a 220 mm wide web and can be cut at up to 25 m/min linear speed (subject to design and substrate)

- Paper, BOPP, filmic labels can be kiss cut, perforated, through cut or simply marked

- Inline operation: the LF220LAS can be associated with a printer and work inline, fully synchronised, reducing the need for operator intervention and reducing significantly the risks of set-up errors, misalignments, etc.

- Roll-to-roll operation: the LF220LAS can also work from pre-printed rolls of media (400 mm)

The Inline ACU-04 finishing solution

Building on the success of the Inline ACU-01 label finishing machine, Eclipse is now strengthening its inline product offering by adding the ACU-04 developed with some key printers. The new machine offers unwinding, laminating, cutting, slitting, removing label excess and rewinding in one, fast touch of a button.

The ACU-04 offers the ultimate tool for small- to medium-sized businesses to make their own customised label in the quantity that they want, when they want to … no more high costs, long lead times and missed communication in the label design.

Some key ACU-04 features and benefits:

- Up to 220 mm wide media

- Lamination facility

- Up to 4.5 metres of label buffer stock between the printer and the finisher

- Compatible with EPSON® Colorworks 6000, 6500, 7500, TSC PRINTRONIX®, VIP Color®

- Splicing table

- Easy webbing of material function

- The complete set-up is fully aligned reducing the risk of misalignment

Experience these new capabilities at Label Expo Brussels

Eclipse Label Finishing Equipment will have a team of experts on hand at Booth 8B21 during Label Expo to showcase these products, answer queries, and explore exciting partnership opportunities that promise to reshape the future of the label industry.

Managing Director Roy Burton, a veteran in the label industry, expressed his enthusiasm about the launch, stating, “I truly believe that the addition of these two models in the Eclipse product range is a game changer for the industry. Nobody else offers these truly inline facilities today and from what we have already experienced the demand for this kind of product will grow exponentially!”

Caption:

The LF220LAS is targeted at medium to large industrial users