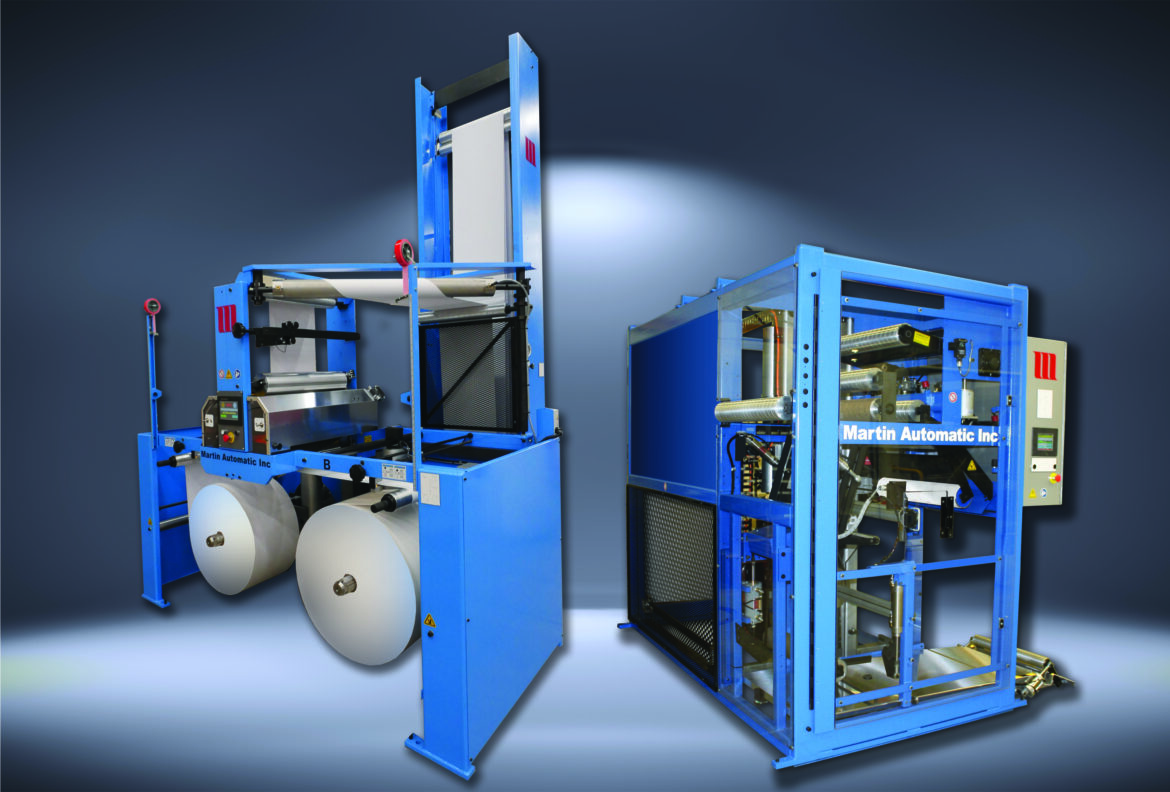

Martin Automatic, the supplier of the original automatic butt splicer to the label industry, is exhibiting the latest versions of its most popular machines at Labelexpo Americas in Chicago. The machines on working display are the spacing-saving MBS unwind butt splicer and LRD transfer rewinder, both available in web widths up to 710 mm and diameters up to 1270 mm.

The MBS supports non-stop unwinding of labels, flexible packaging, shrink sleeves, laminates and light paperboard for the most demanding and changing production environments. Featuring Martin’s patented linear sheer butt splice unit and integrated roll loading mechanism, its versatility accommodates automation of any web converted by label converters around the world.

The LRD is a two-spindle non-stop transfer rewinder that features the same versatility and adaptability as the MBS, but for the delivery end of the press. The LRD rewind features a moving cantilevered spindle arrangement that allows rewinding and automatic doffing of rolls as small as 203 mm in diameter with only two spindles. Minimum roll diameter will depend on the decision to glue or pre-tape cores, material caliper and line speed. The AC vector drive package, with dancer tension control, adds tension accuracy and flexibility.

The rewind is designed to minimise cycle time and facilitate customer-supplied roll handling to fit their particular needs. In addition to the automatic transfer, it features automatic unloading of finished rolls and is easily fitted with a slitting module that can also accommodate automated differential winding.

Caption:

Automatic unwind/splicer and non-stop transfer rewind featuring automatic roll unloading