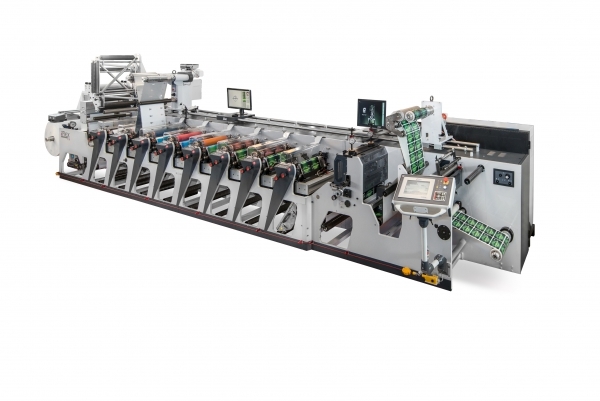

iflex fills a gap in technology supporting small to large label converters who need to produce in one pass all types of PS labels with the least amount of waste.

iFlex represents the “conventional” solution to fight in the “digital world” thanks to the highest level of efficiency in its category.

iFlex is a label press characterized by ease of use, efficacy of operation, least wastage and extremely low maintenance level. Several innovations characterize this press, all aiming at simplifying the printer’s work in reaching the highest quality, effortless. They include servo-assisted tension control of the substrate to guarantee the best flexibility on substrates and the register stability.

iFlex comes with the shortest web path in narrow web print industry (just 1.300mm in between two print units) for unmatchable savings on start-up and machine re-start.

iFlex is the only narrow web press to offer printing cylinders with direct-drive technology, which leads to incredible results in print quality and saving of consumables. No motors and gears’ maintenance and tolerances any more.

iFlex machine handles the widest range of print repeats: from 5” to 18 ½’’ in order to reduce dramatically plate making cost and compete even with digital label printing machines.

iFlex has a robust but compact design and it’s engineered to last. Year after year you will always deliver the same print quality, thanks to this almost gear-less solution.