Koenig & Bauer has ramped up its environmental and sustainability offerings by unveiling future innovations for customers as the build-up to drupa continues. The next-generation technologies in packaging décor printing technology and flexo specialities were explored in depth during the Digital & Webfed Technology Days.

With customers now able to experience fully interactive event experiences, Koenig & Bauer focused its recent Technology Days on presentations for brands and customers with live product demonstrations on the CI Flexo and RotaJET presses. Over 150 attendees immersed themselves in a story of Koenig & Bauer’s specially created brand, ‘Happy Farm Box’, on which the two-day event was built.

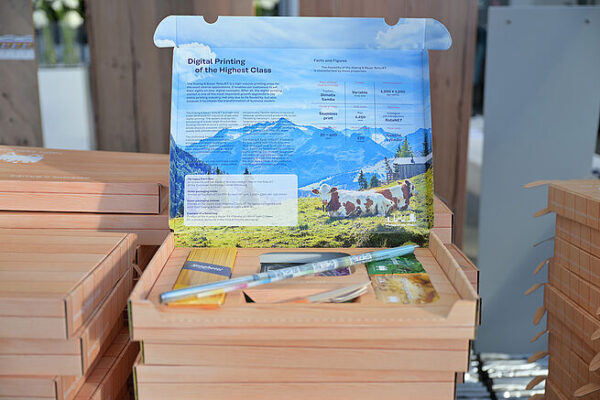

The ‘Happy Farm Box’ impressively shows the scope of services offered by Koenig & Bauer as a holistic solution provider for the packaging industry: from digital direct corrugated cardboard printing to digital printing to high-end CI flexographic printing, track & trace including individual coding, punching and folding box production.

Latest technology advances were shown such as flexo printing on bio-based and biodegradable film with food-safe inks. Other components of the showcase boxes or pouches were printed digitally with water-based, food-safe ink and primers. Examples were shown of print-on-demand with less waste, in-flight job changes on an industrial scale. Other diverse application possibilities also included sophisticated folding cartons, pouches, fibre-based packaging and corrugated.

Another highlight involved showcasing the creative and sustainable possibilities of digital print with the potential of Artificial Intelligence in the decorative industry, whereas there have been limitations in the past by the circumference of the cylinder.

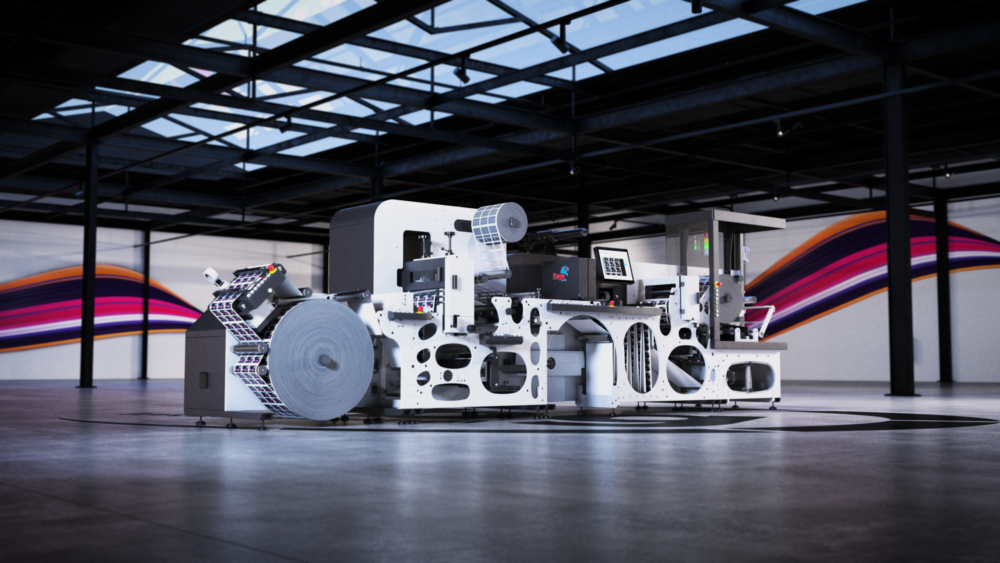

Koenig & Bauer unveiled its XD Pro CI Flexo next-generation press, which combines almost 50 years of flexo printing market experience with world-acclaimed engineering. Designed to meet just-in-time market demands for short-run production agility for added-value sustainable flexible packaging, the press takes performance reliability, process consistency and efficiency to new productivity levels.

Koenig & Bauer Coding showcased limitless possibilities from live coding on pasta packaging using an udaFORMAXX and an alphaJET 5 X as well as individual laser marking of metal drinking straws and lasered logos on apples. Aesthetically appealing but also environmentally friendly coding on wooden cutlery with CO2 laser was also presented.

“This was a phenomenal event featuring technology demonstrations, expert Tec talks, inquisitive interaction and a factory tour that included watching casting in action in the foundry”, said Christoph Müller, CEO Koenig & Bauer Digital and Webfed. “Over two days we were proud to bring together a diverse group of international participants – including globally recognised brands and household customer names – who provided the delegates with incredible, exclusive, insights into Koenig & Bauer’s innovation pipeline and an exciting preview of the groundbreaking, sustainable developments that will shape the industry’s future with rising environmental requirements.”

Caption:

The ‘Happy Farm Box’ shows the scope of services offered by Koenig & Bauer

Learn more about Koenig & Bauer CI flexo printing machines