In its remarkable journey of redefining flexo printing, Labelmakers Group stands as a notable sponsor of the latest BOBST DigiFlexo technology. Established in 1987 as a self-adhesive label printer, Labelmakers Group has evolved into Australia’s leading and most innovative supplier of packaging solutions, backed by a trans-Tasman committed team.

With a diverse product range encompassing shrink sleeves, pressure-sensitive labels, linerless wraps, pouches, folding cartons, leaflets and blister foil, Labelmakers is the ultimate one-stop shop for innovative packaging and printing needs.

Dedicated to providing environmentally optimised and sustainable solutions, Labelmakers Group operates a large array of inline flexo presses. Notably, this includes six different versions of the BOBST MASTER M6, each tailored for either the long-run Australian beverage industry or the short-run faster time-to-market products utilising one ECG technology, coupled with DigiFlexo automation.

Adam Bamford, Managing Director of Labelmakers Group, is a key supporter of the BOBST digital flexo technology. He shares, “As a long-standing customer of Bobst in the folding cartons space, we have now chosen to partner with BOBST in our label and shrink sleeve production. BOBST’s innovative DigiFlexo technology supports significant press automation, reductions in our waste figures, and delivers outstanding image quality for our diverse customer base.”

The role of BOBST

BOBST not only provides cutting-edge technology but also supports customers at every step. Its expertise extends from profiling and job conversion to workflow, platemaking and plate mounting. As colour matching shifts from the print room to the prepress department, BOBST ensures that customers are equipped to maximise the benefits that oneECG can bring to their business.

BOBST’s oneECG technology represents a vital leap ahead in flexo printing, redefining industry standards and pushing the boundaries of efficiency, quality and sustainability. With Labelmakers Group and Adam Bamford as enthusiastic supporters, converters can look forward to a future where colour consistency, cost savings and environmental responsibility go hand in hand, all while ensuring their place in the global market.

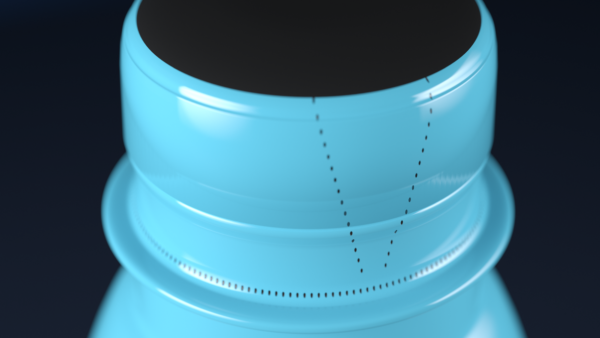

Caption:

The BOBST MASTER M6 in a ten-colour configuration installed at Labelmakers’ Victorian site

For more information contact https://www.bobst.com/en/about-bobst/find-your-local-contact/