In 1963, at just 29, Angelo Bartesaghi founded OMET Srl (an acronym for Officina Meccanica E Tranceria, i.e Mechanical Workshop & Blanking) with a vision to design and create special projects for different markets and industries: printing machines, tissue machines and ball bearings. This year OMET celebrates its 60th anniversary.

Angelo Bartesaghi was very demanding of his collaborators: he demanded excellence, but knew how to recognise merits and placed great value on teamwork. One of his mottos was 1+1=3: collaboration is greater than the sum of the single contributions.

The first OMET collaborators, crucial for its growth, remained in the company until their retirement. Nowadays job changes are frequent, but loyalty to the company is still widespread at OMET, where attention to people always comes first.

In 2010 OMET was awarded the Global Award for Continuous Innovation which recognised its success in innovation, as a result of the company’s ability to read the market’s requests and to develop them into projects. Tailormade is the essence of OMET’s approach: never standardise machines but use smart technologies to globalise knowledge.

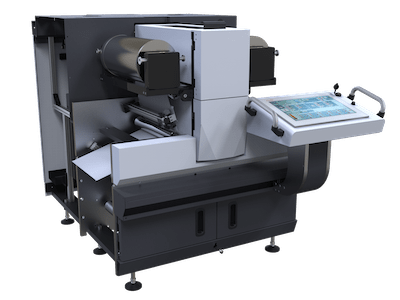

As global leaders in flexo and combination printing presses, OMET offers a combination of printing solutions to help packaging printers achieve sustainability, differentiation and profitability.

While OMET is now an international leader in its sectors, it’s still a family business. The Bartesaghi family has led the company up to the present day, sharing a deep sense of belonging among all those who work there and values like honesty, fairness, transparency, respect for work, environment and people.

Year after year, OMET has grown worldwide, thanks to the trade fairs that showed its technology throughout the world. This year at Labelexpo along with the XJET and KFLEX machines, Omet presented its new digital service solution, known as Sfera, which monitors all connected machines in real-time to analyse related data and help customers make better operational decisions.

It is a pioneering vision for the industrial future, where AI and IoT come together to create unprecedented machine management. In addition to integrating data analysis tools, the Sfera monitoring platform leverages artificial intelligence, machine learning and anomaly detection algorithms. The goal is to gain advanced insights from the collected data and predict possible future problems or trends. This data, together with OMET’s expertise, can become a useful tool for entrepreneurs to optimise their machinery.

The main services offered by Sfera for OMET clients are: Efficiency Analysis; Bottleneck Detection; Process Telemetry; Energy Consumption; Preventive and Predictive Maintenance; and Job Executor.

With this innovative proposition, OMET puts a powerful tool in the hands of its customers to meet the challenges of Industry 4.0. The machine becomes the virtual touchpoint between the customer’s team and OMET, which, thanks to its know-how and expertise will be the key to optimising the production process and maximising productivity.

Currie Group is the ANZ distributor for OMET

Caption:

With Sfera the raw data generated by the machines is transformed into valuable insights useful at every level of control, from the operational level to the top decision maker.