UK manufacturer ABG International, continues to dazzle the label world with its constant flow of new products for the world label scene. Labelexpo Chicago was no different, with an array of products that keep the manufacturer at the forefront of finishing technologies around the world.

A digital technology from CERM – Jet Effect:

Mark Daws Currie Group Director – Labels & Packaging ANZ, said this latest technology on the ABG comes from JetFX, the supplier who is also building the GEM digital program for HP Indigo – “It’s the same technology as GEM and allows a converter to undertake digital embellishing using cold-foil, and hi-builds, without the need for tooling, because of its digital nature.”

He said this addition would be available for converters in the coming months, and can be retro-fitted on to Digicon units in the market.

CERM JDF keeps you aware how you are running:

Ben Gregory said ABG also had the JDF from CERM on display for the first time. “It is a CERM MIS implementation, where the link between CERM and the offline finishing device – in this case a finishing machine from ABG – is organised via JDF communication. The goal is to automate the information flow from the MIS to the device as much as possible, and to return valuable information from the device to the CERM MIS.

Every graphic now will have JDF compatibility, and we’re working closely with CERM. Here at the show, they are tracking live data from the presses on the booth. And they’ll be able to monitor and record how fast the machines are running; what the waste is; how much downtime they have. It’s all on the screen. And it can be integrated into any MIS system.”

Mark said it gives a picture of the performance of the machine in real time, and it can also send data to that machine to use for set-up, and all the required job-run data. “This can be recorded on the JMF side of it where you are monitoring the data live from the press.”

ABG’s Digilase new generation also on show:

Another ABG Technical Executive Paul Klaxton, explained ABG’s newest laser system. “We have gone from previously having two 100Watt lasers to one 4900Watt laser. And over and above that, we are showing our Workflow system which is JDF. Pushing the start button, brings up a barcode; which sets up the new job without stopping; and automatically switches over to the new job. Then on the fly, it automatically sets all the back-score positions, continues on and resets all the individual knives, so the operator only pushes the start button once.

“He runs it to the end and it’s ready for recall. And so you can have multiple jobs loaded at any one time. A new one coming, the one running, and the one that is being cut and rewound – all without any set-up.”

He said you can run the machine, read the barcode and see the reports – you don’t miss a repeat. “It goes into a slow mode, it cuts every one of the previous job and then starts cutting the new job – all without any labelstock waste. It sets-up again and it will then automatically set the knives. And once that is completed, it is ready to start again.

“A brand-new release from ABG is the Horizon,” said Mark, “a bi-directional table-top rewinder.”

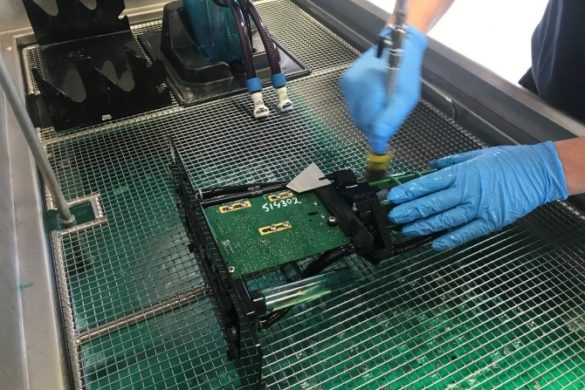

Phillip Ledgschwendner from ABG’s Design Department, introduced the product to visitors on the stand and said: “This version is equipped with a fully-integrated camera system so you can see the error on the screen; the location of the error on the label; and what it looks like. This machine brings the faulty label back to the splicing table so the operator can inspect it and decide whether he wants to pull the label out and replace it, or what other action is needed.”

(Pic caption:) Ben Gregory said the aim is to automate the information flow to and from the finishing machines and the MIS system.

(Pic caption:) Ben Gregory said the aim is to automate the information flow to and from the finishing machines and the MIS system.

Phillip said this inspection rewinder was also equipped with an inkjet head for back-side/front side numbering. “This is particularly useful for some pharmaceutical workflows, where you inspect the label and every accepted label is marked on the rear with a number. With this bi-directional machine, you don’t lose any labels, because every label is inspected and if it picks up an error, the machine stops, runs backwards and positions the error. This error has to be dealt with first and then the inspection continues. So you don’t miss any errors, and if you replace that label, then it is re-inspected again to ensure that everything is correct.”

“This unit is linked to the slitter/rewinder,” added Mark, “and once the tracking and identification of errors is completed, you take off the slit-down rolls.”

“We can also implement an ID system,” continued Phillip. “Where we put the filing workflow system on the end, so that every label that has been identified with a defect on the printing press, Digicon, or turret, produces a closing label and by scanning that label, you have the complete picture of which machine it was printed on; on which roll; which lane on the roll. It brings up all the error positions and that can be run just on the table-top rewinder and be replaced by new labels. All without having another inspection system.”

He said another system working on the stand, was a dancer system for tension control. “It ensures the tension is not diameter dependent, and always stays the same. So we have very precise tension control which enables us to have quite loose rolls. Another feature facilitates the removal of very loose rolls. If you’re taking them off from the top, you have the potential to damage the roll and the cone, but this machine allows you to take them off easily and without damage.

“And I think one of the best features is that it is height adjustable, so you can use it sitting or standing.”

For more information on the Digilase or new Horizon rewinder, contact Mark Daws at Currie Group on Tel: (03) 9810 8888

(Pic caption:) Mark Daws Currie Group (left) with Phillip Ledgschwendner from ABG were guiding visitors through the many benefits of the new Horizon bi-directional rewinder.