Gallus Group has celebrated its 100 years in business with the official opening of its new industry hub: the Gallus Experience Centre, as well as announcing the launch of three new products across its portfolio. Designed to be a central touchpoint for the entire labels and narrow web landscape, the new centre is dedicated to facilitating the future success of the industry, fostering collaboration to drive innovation and sustainability and accelerating the industry’s ‘digital transformation’.

Dr. Ludwin Monz, CEO, Heidelberg, noted: “With labels and packaging now representing 50% of the Group’s total sales, the new digital and automated solutions we see introduced by Gallus today play an important role in the future of Heidelberg. As a result, Gallus is an important pillar within the company’s growth strategy, and we’re more committed than ever to its long-term future.”

Packaging printing is one of the strongest growth areas in the printing industry, representing annual growth of over 2% in global print volumes. Together with label printing, it is an important core area for Heidelberg.

In line with its dual-track strategy, Heidelberg is also focusing on growth in digital printing, which offers some of the greatest growth opportunities in the printing industry. One third of all labels worldwide are already printed digitally today. Digital printing is thus driving change in this promising market segment, with inkjet growth of around 6% a year. Heidelberg intends to expand its position here with the Gallus One.

To further drive the labels and packaging ‘digital transformation’ and help solve current labour shortages and increases in costs, Gallus unveiled a revolutionary new Heidelberg Customer Portal (HCP) that automates almost every customer touchpoint.

In an industry first, future iterations of the solution will also provide predictive capabilities utilising artificial intelligence (AI) to provide recommendations to increase productivity, reduce maintenance and boost profitability. The new platform is expected to save customers, on average, up to 35% in both time and money.

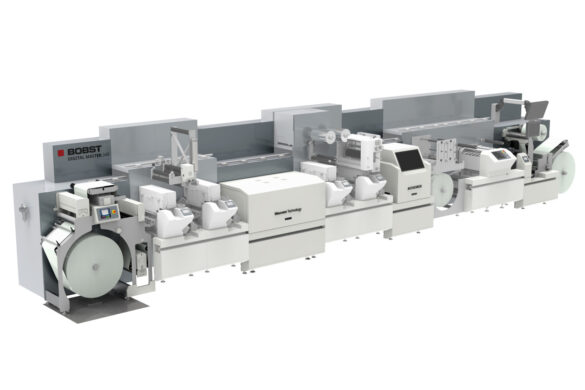

Further increasing its Total Cost of Ownership (TCO) advantage for label production, Gallus also launched its new Gallus One with Converting. This solution brings everything inline and features a digital printer with an inline flexo station, a semi-rotary die cutter that can change a job within one minute and process up to 70m per minute, and vision inspection systems to ensure the highest level of quality and minimise waste.

The company also announced the option to upgrade an existing Gallus ECS 340 flexo press with a digital printing unit (DPU), transforming it into a Gallus Labelfire 340 hybrid press, but without the additional platform investment. This means that customers are now able to access all the flexibility and versatility of digital printing, with the reliability and precision of conventional printing and further processing technology.

Dario Urbinati, CEO, Gallus Group, concluded: “This week is as much about the next 100 years and what we do next. This is why we’re excited to look beyond the graphic arts toward other industries – learning from how they’ve leveraged new technologies to welcome in the new digital age and cater to the next generation – so that we can modernise the labels and packaging industry and further increase our future success.”

Caption:

The new Gallus One inkjet system offers a competitive total cost of ownership (TCO) in digital label printing.