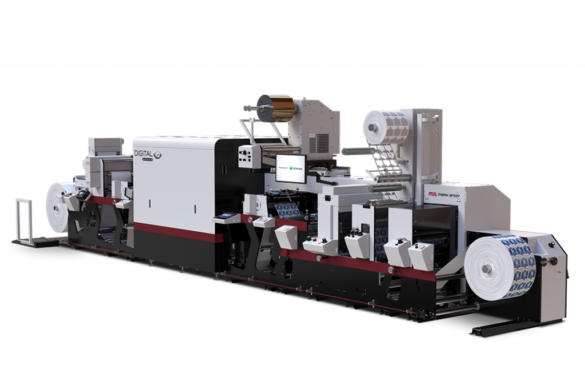

The merger of Maxcess and Rotometrics in 2020 created the global leader in innovative products and services for web handling solutions. With this merger came opportunity – from increased technological innovation to value-added Industry 4.0 solutions and expanded geographical markets, focusing on a strategic approach of ‘think global, act local’.

Today, Maxcess has 2,200 employees, eight brands, 30 manufacturing and development sites and 20,000 customers in 90 countries worldwide making it by far the largest global player in the industry segment. The Maxcess brand includes names such as Componex, Fife, Tidland, RotoMetrics, Magpowr, Webex,Valley Roller and Maxcess Vision. Originally these were all small companies with different technologies that were brought together into one platform so that customers can better integrate individual components.

The roots go back to 1939, when Fife was founded in Oklahoma City and launched the first hydraulic web guiding system; other companies such as Tidland, known for cutting systems, and MagPowr, specialising in drive and brake technologies, followed. The companies are owned by with private investor with long-term vision, and as Maxcess is privately owned, it is able to pursue a long-term, sustainable strategy.

“Maxcess provides solutions that help you work better, faster and smarter,” says General Manager Alex Kasyanov (above right). “Maxcess saves you time and money by optimising your peak output performance. We do this by leveraging the world’s best web handling brands, offering customised end-to-end web handling solutions. We manufacture all of our components to meet the highest standard of precision, with the deep application knowledge behind how each component works better together across your converting line. All to provide unmatched product integration and precise positioning from unwind to rewind.”

Customers are asked what they need and Maxcess develops solutions from that. Individual customer needs are the biggest drivers; and those needs come in a wide variety. In the past, the maxim was ‘engineered to order’; today it’s ‘configured to order’. The result is modular, globally standardised products and services that ensure customers can run better, faster and smarter.

In the future, Maxcess will continue to focus on generating added value for its customers while incorporating sustainability. David O’Reilly, Sales Manager ANZ, (above left) says: “Sustainability plays an essential role across the company. We encourage our customers to shop locally to reduce their carbon footprint and save on freight. Maxcess is committed to reducing landfill volume, hazardous waste, energy usage and wastewater by 3% year over year.”

Alex Kasyanov adds: “Maxcess continues to invest into new technology at the facilities and plants around the world and Australia is no exception. Our improved capabilities and product offering will allow our customers in Australia and New Zealand to run their operations better, faster and smarter. We strive to be a strategic partner for our customers to meet and exceed their expectations.”

Caption:

Alex Kasyanov, General Manager Maxcess, and David O’Reilly, Sales Manager ANZ